A cutting-edge, open source, cloud-based manufacturing ERP system that handles subcontracting and capacity planning, streamlines the production cycle, and more!

Integrate your shop floor and production planning. Real-time coordination between all of your business verticals is facilitated by ERPNext’s customer management, sales orders, inventory, purchasing, accounting, and financial reporting features.

Any cloud manufacturing software relies on a bill of materials (BOM), and a well-defined BOM guarantees accuracy and robustness. The finished product is at the top of the BOM in ERPNext. Along with product codes, part descriptions, quantity information, price information, and other specifications.

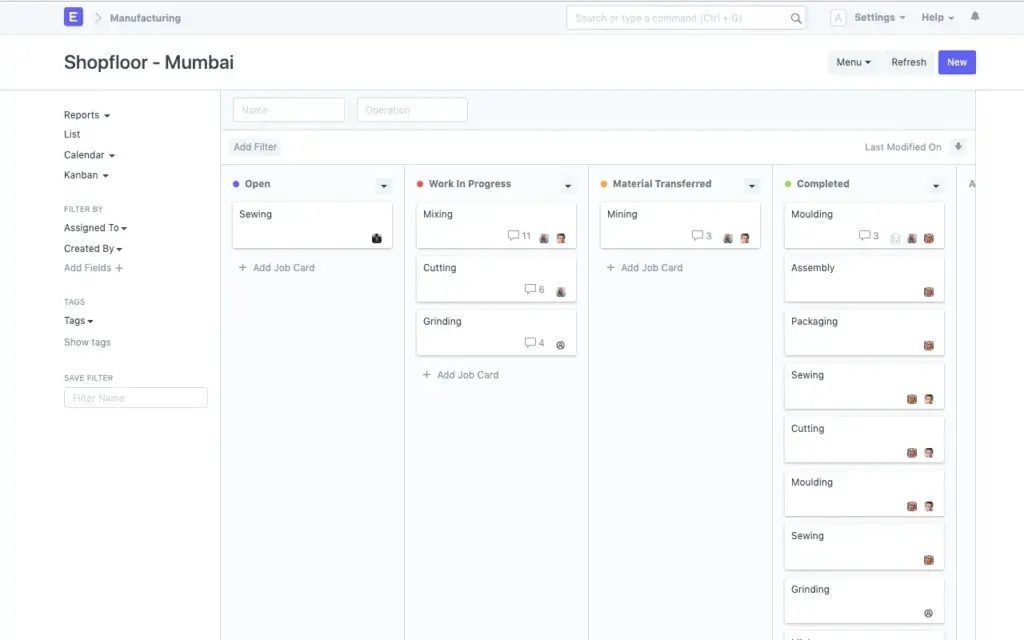

You can automatically record daily operations on your shop floor with the help of the job cards, operations, and workstations features in ERPNext. On a single screen, you can see the current status of the work being done to manufacture products, the locations of each workstation, employee assignments, and the pending steps for each work order.

Does your company use a supplier to outsource certain processes? Check out ERPNext’s subcontracting functionality. It makes it simple to track suppliers’ labour and operations and to supply raw materials. Based on the price of purchased services and raw materials, finished goods are valued.

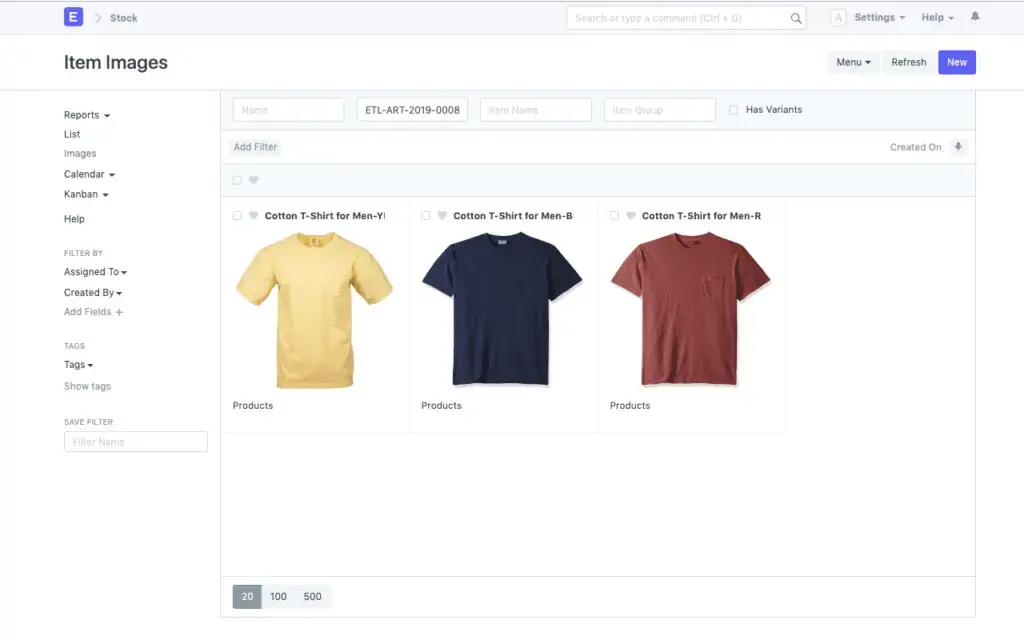

Let’s say you manufacture t-shirts in various sizes and hues. Each type of t-shirt and any item variants that exist for that type must be tracked. The main item is saved in ERPNext as an item template, and each variation is saved as an item variant. For each item variant, any attribute, including colour and shape, can be stored.

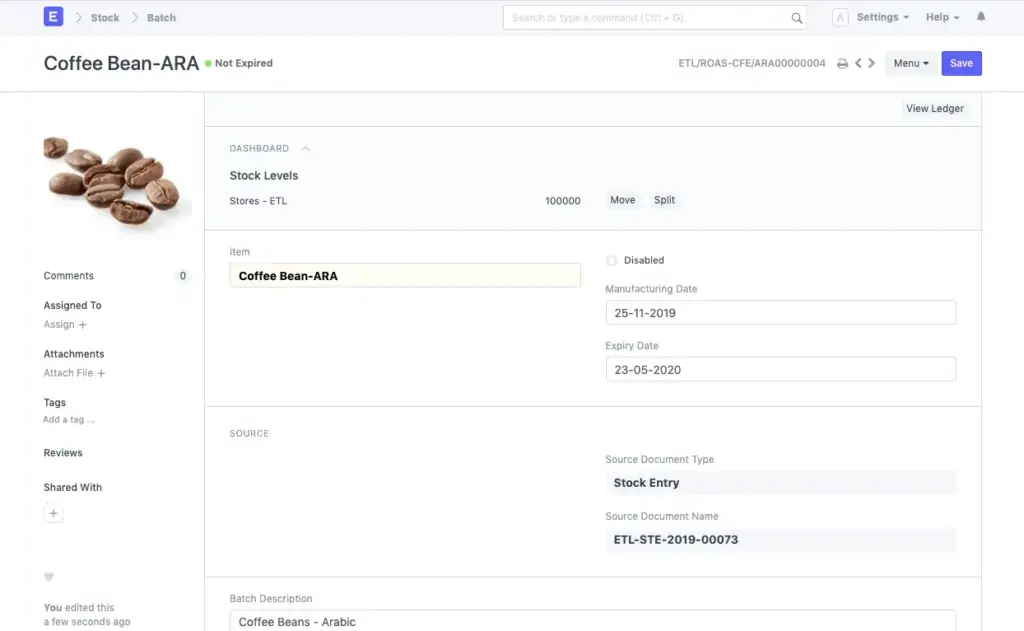

The integrated inventory of ERPNext makes managing batched items simple. The manufacturing dates, expiration dates, and other information for each batch are maintained in its real-time view of product availability. Even better, you can use the camera on your device to scan item barcodes for quick stock searches and data-driven decisions.

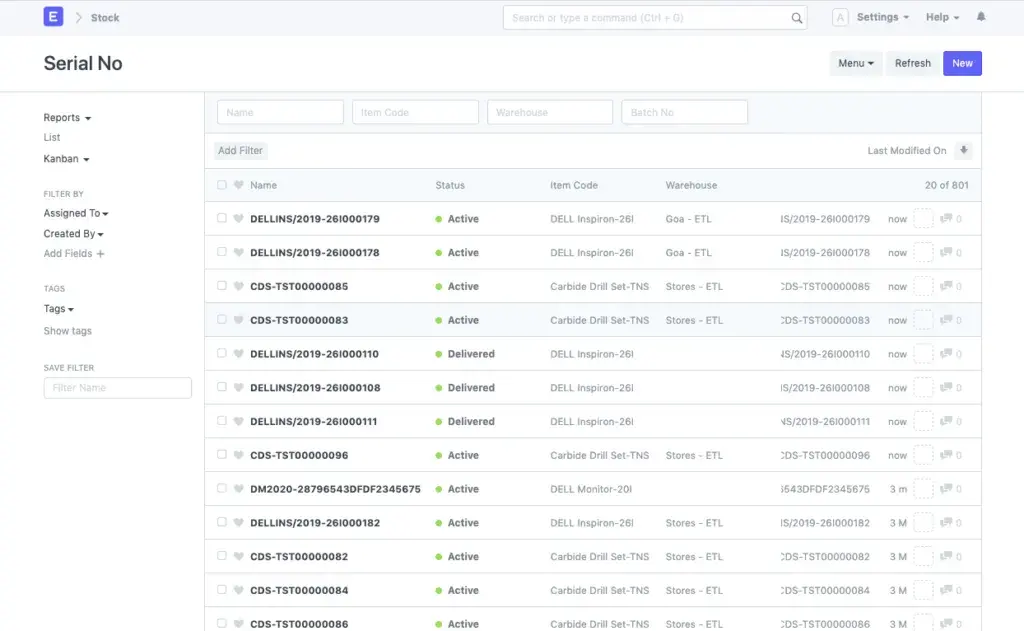

To identify units specifically, use serial numbers. Create naming series, and ERPNext will generate serial numbers for new stock automatically. To easily search through all of your stock, you can even scan item barcodes using the camera on your device.

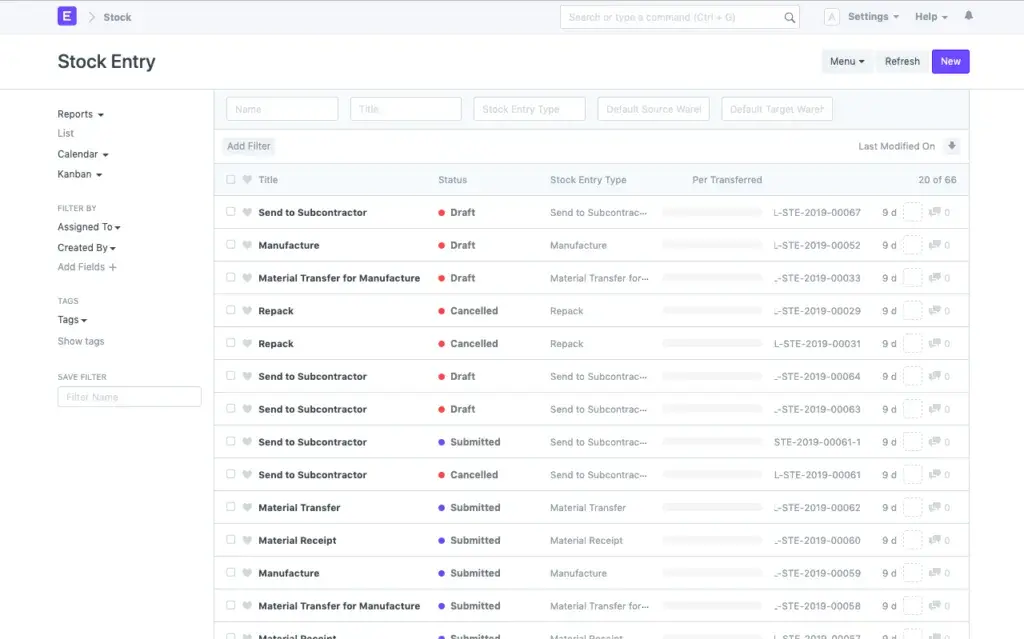

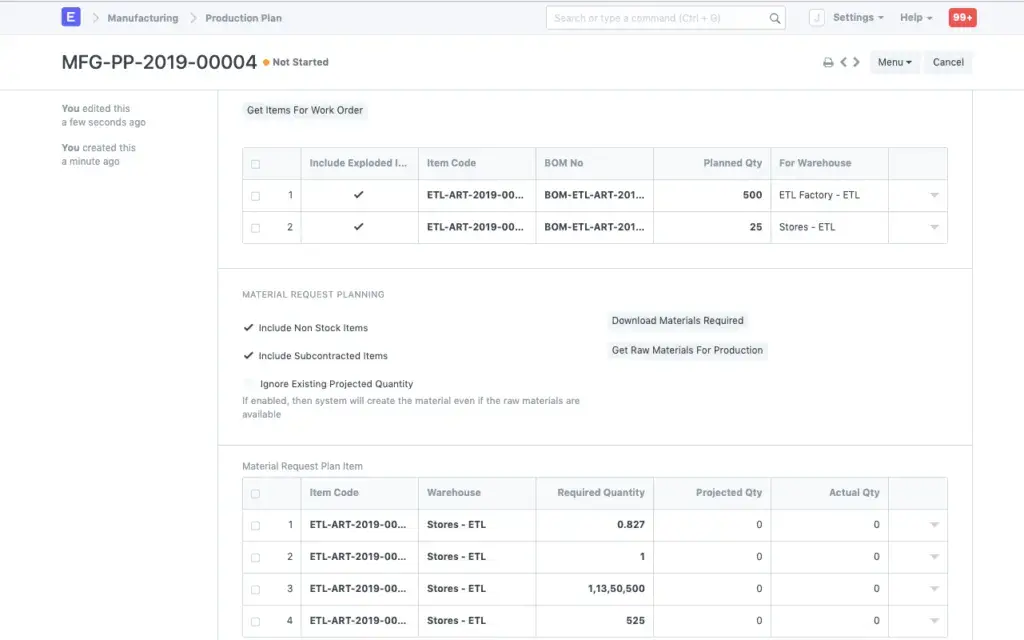

ERPNext will display every element of your MRP, whether it be a work order against sales or a material request. Monitor the material usage of serialized or batch inventory to reduce costs and achieve zero resource wastage.

Based on the resources available for active production orders, optimise your workstations. Create a capacity plan to identify and remove bottlenecks on the shop floor. Additionally, you can keep track of and control planning schedules for a predetermined period of time (30 days, 45 days, etc).

Don’t let systems prevent you from precisely measuring your materials! Keep track of the various measurement units used for your inventory. Make smooth sales, purchases, and stock transactions possible by setting up conversion factors directly in the item master. The system will handle all conversions.

You can conduct stock audits using the quick stock balance report to confirm the inventory in the warehouse and compare it to the inventory listed in the system. Start counting by simply scanning a barcode with any device (a barcode scanner is not necessary!).

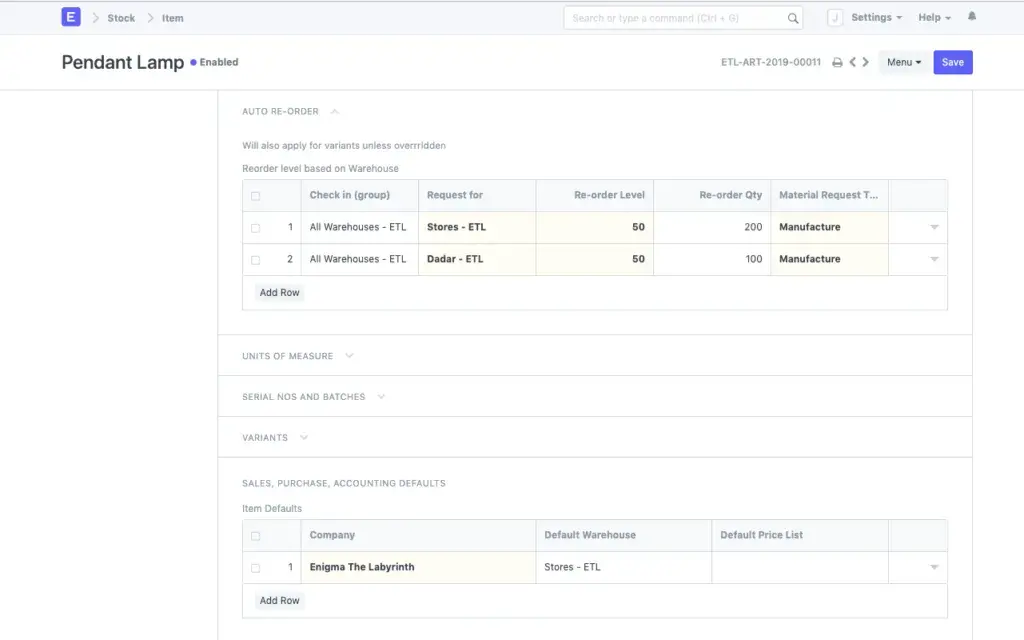

Keep tabs on an item’s reorder level to avoid stockouts. ERPNext will automatically generate a material request if the stock level falls below the reorder level. This lessens the likelihood of stock exhaustion and helps you replenish inventory at the ideal moment.

Develop your own unique cloud-based manufacturing ERP system. By including custom fields in your forms, you can map your most crucial data. Create custom print formats, hide fields based on user roles, and alter form behaviour all without writing a single line of code.

Can’t find your language? Help us translate: https://translate.erpnext.com

Whatever industry you belong to be, we offer unique, scalable, and robust solutions that will help you manage your business the way you want.

There are tasks in every industry that are susceptible to becoming stuck in data, verification, and analysis. By implementing RPA in your organization with the help of ERPKA, you can streamline those processes and free up your workforce to concentrate on tasks where they can have a significant impact.

Copyright © 2022

ERPKA provides small, medium, and large businesses with cloud-based, tailored, user-friendly, and intelligent enterprise solutions built on the ERPNext Platform in order to give them complete business control and complete operational transparency.

Copyright © 2025